Cor Team Tomasz Dziaduszewski

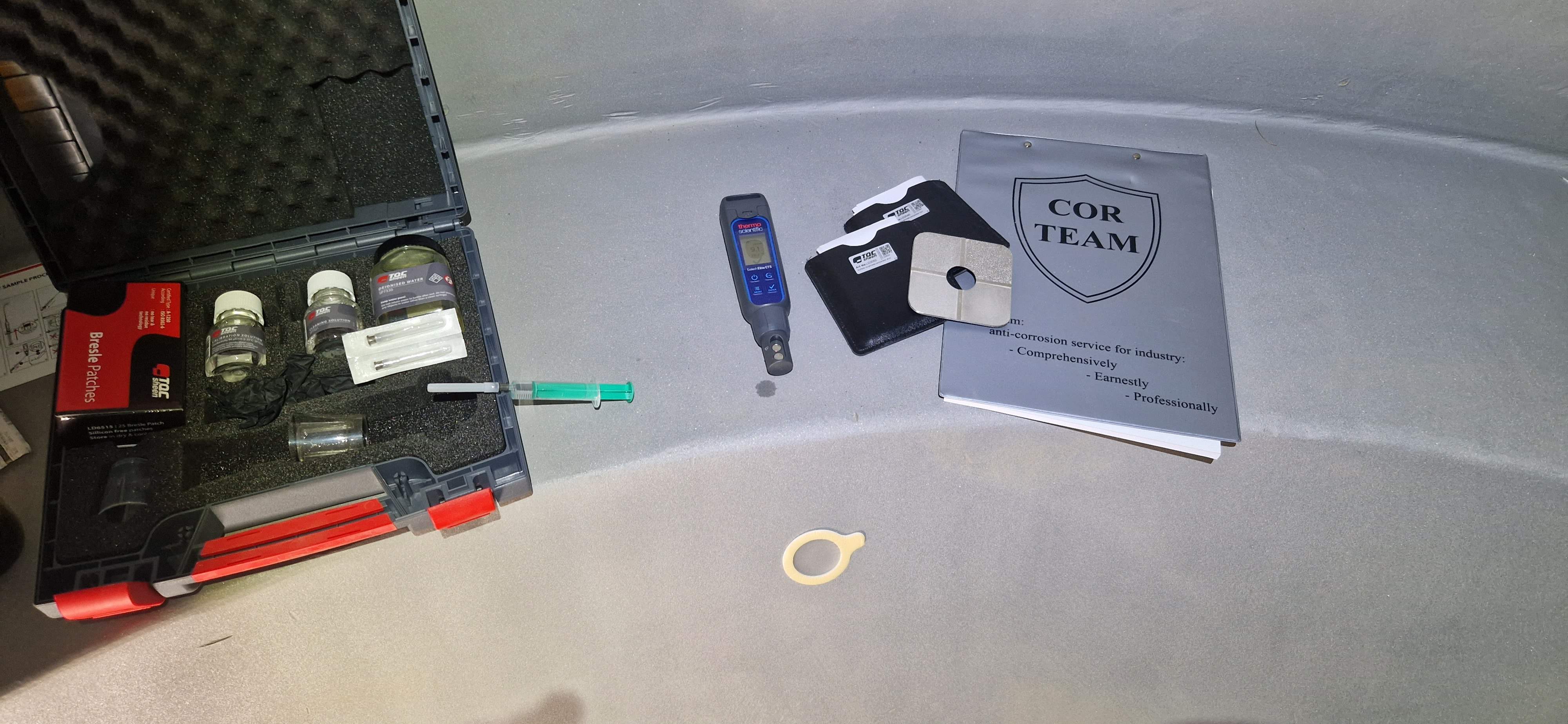

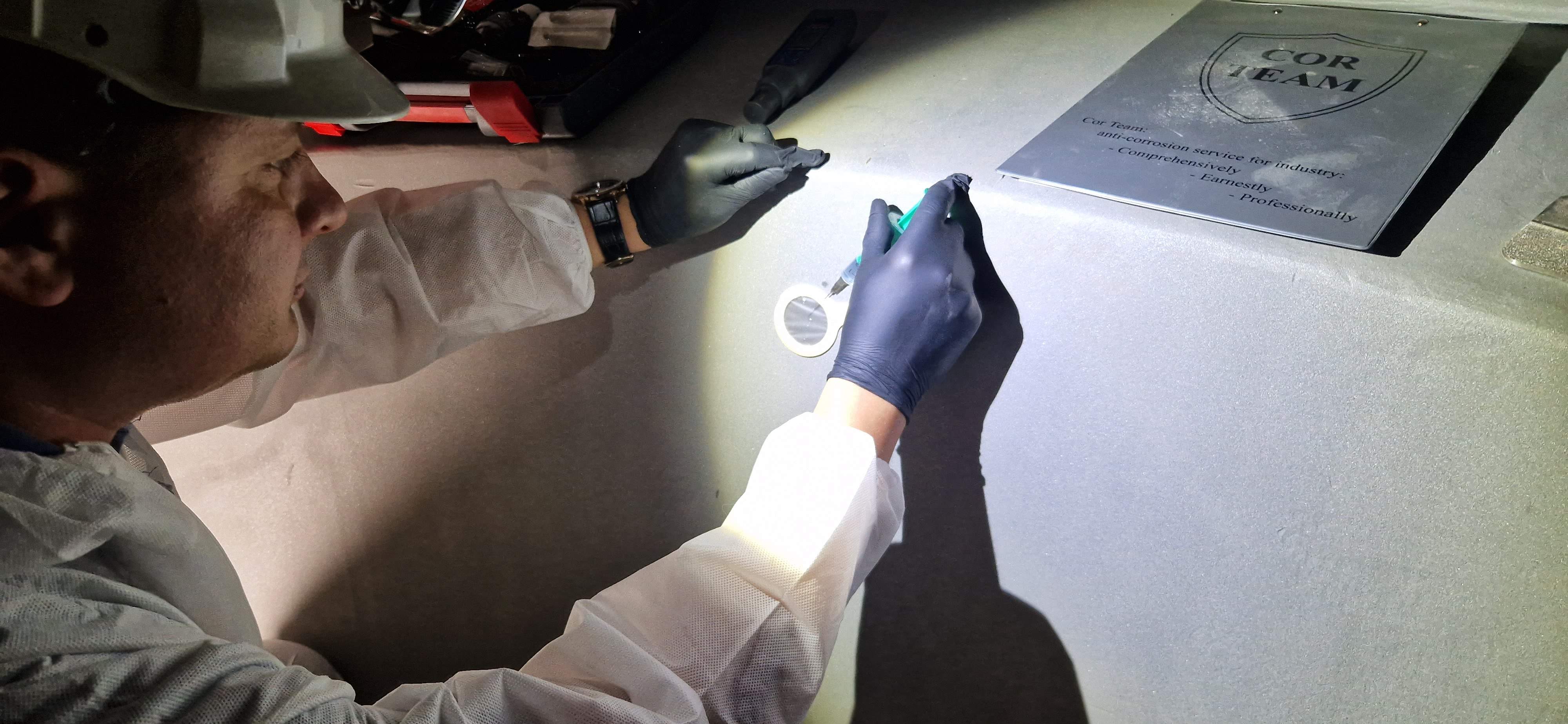

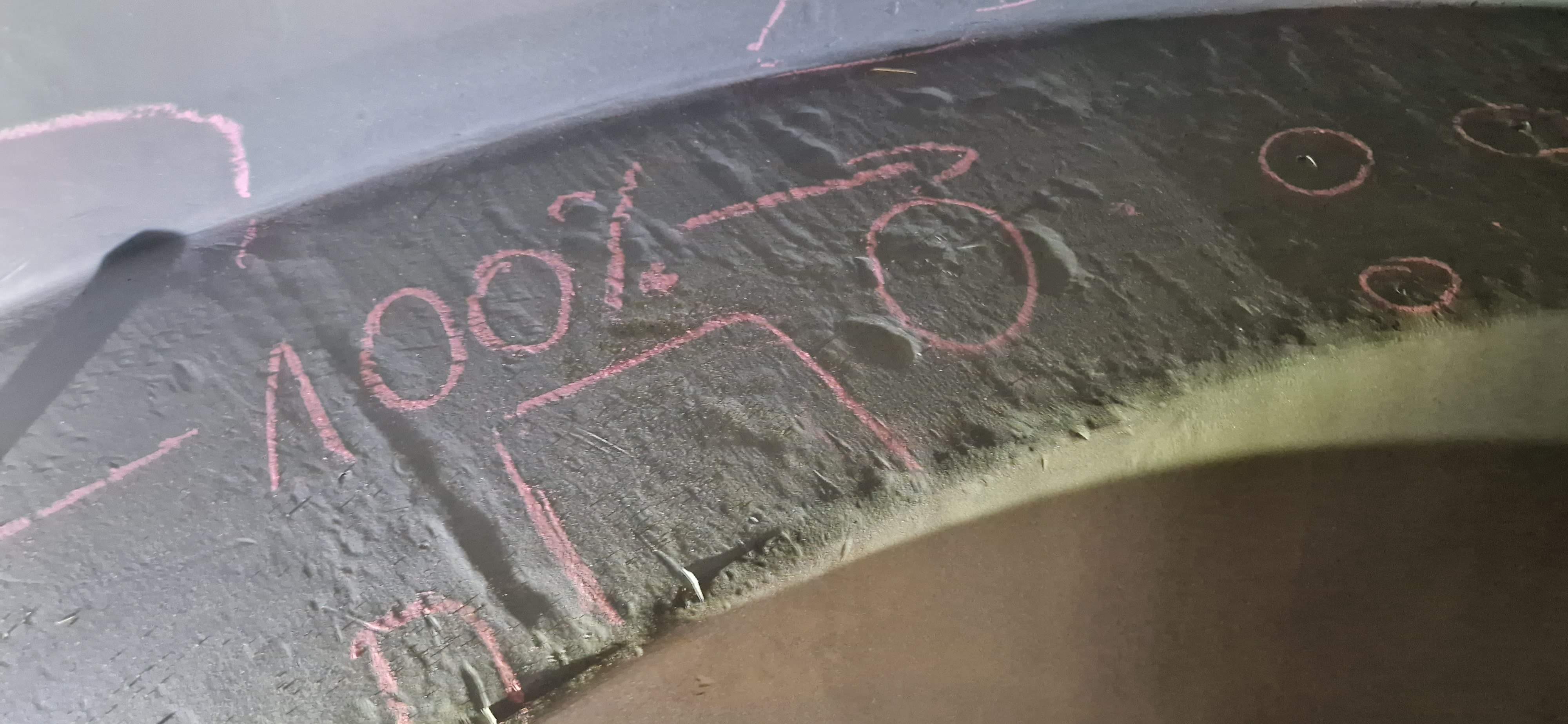

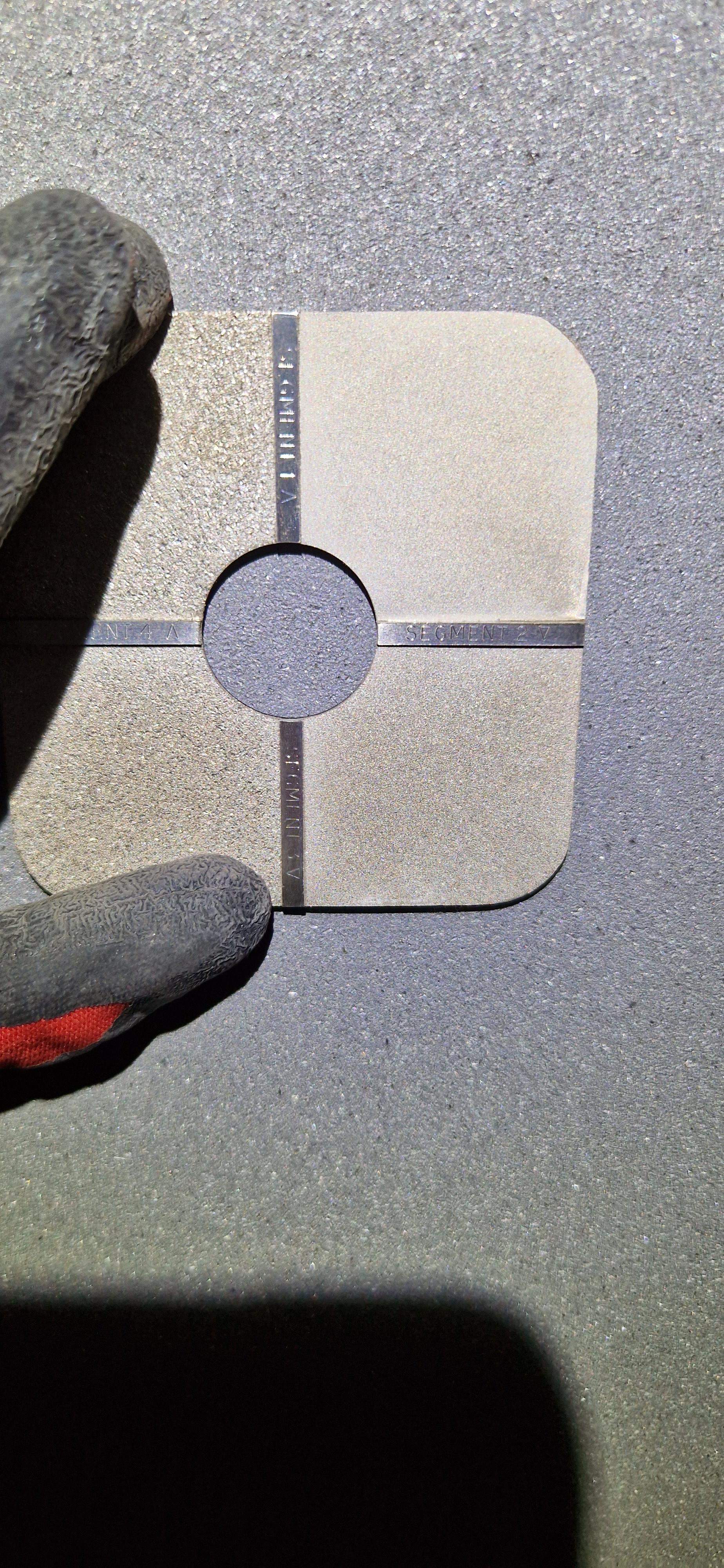

The company is me. I am the company - Cor Team - an expert in anti-corrosion for industry. Inspector with international FROSIO certificate (level III, the highest) conduct inspections of the condition of anti-corrosion coatings, perform investor's supervision, advise and design anti-corrosion systems. I'm working for industrial plants, power plants, waste incineration plants, supervising works carried out by subcontractors. My tasks include cost optimization of anti-corrosion works, selection of the correct materials, supervision over the appropriate application, in accordance with DIN standards and the Investor's requirements.

Areas of activity:

• for design offices - analysis of compliance of the design of steel structures with the ISO 12944 standard.

• for manufacturers of steel structures - quality assurance in external paint shops. Supervision of the coating process.

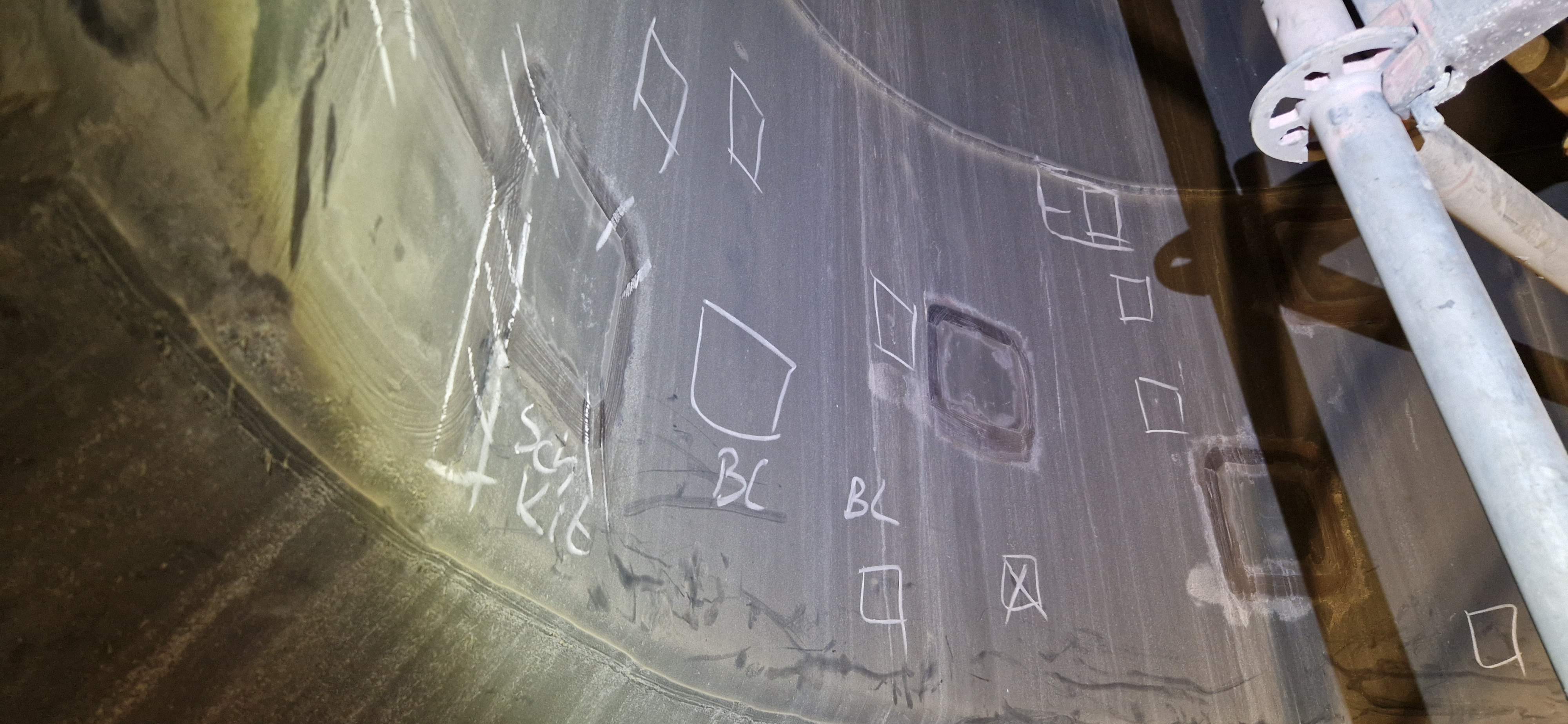

• for the power industry, waste incineration plants and the chemical industry - testing the condition of anti-corrosion coatings, investor's supervision, selection of appropriate materials.

Cor Team - expert in rubberlinig, flake-coatings, PFA, chemoresistance brick lining.